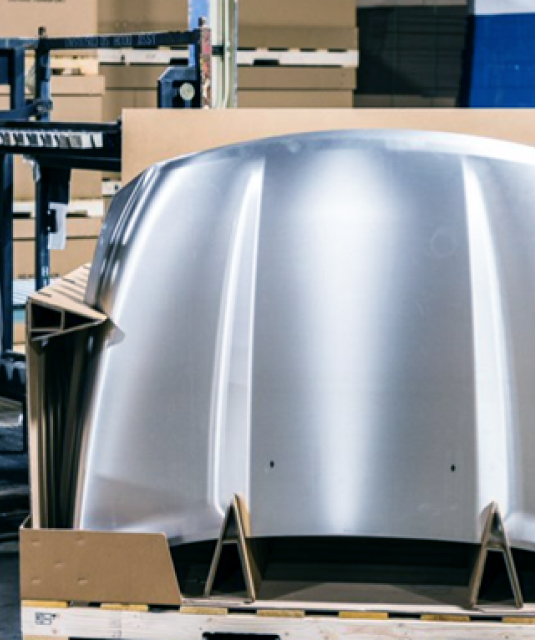

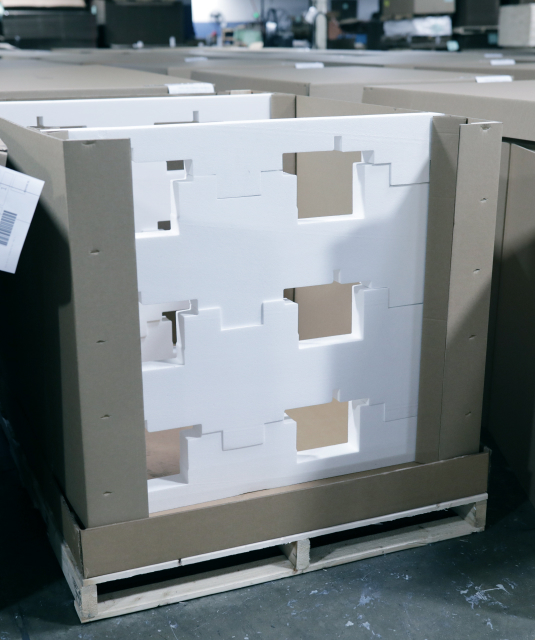

Safely and efficiently transporting vehicle components creates several challenges for automotive packaging.

Protecting vehicles and parts from impacts, vibrations, and environmental factors remains the primary concern.

Space utilization and sustainability are also essential to parts and automotive manufacturers.

We build packaging for automotive components and parts to withstand the harshness of transportation, including handling, loading, unloading, and shipping.

Our packaging materials are chosen for their durability and ability to absorb shock and vibrations, providing a cushioning effect for the parts or vehicle.

In addition, we test and certify the packaging to ensure that it meets industry standards for protection and safety during transportation.

To achieve this, we use various materials such as foam, plastic, cardboard, and metal to create customized packaging solutions.

For instance, plastic and foam materials create airtight packaging that keeps moisture and dust out, while metal creates sturdy packaging that can withstand harsh weather conditions.

We also use specialized coatings or films to provide additional protection against UV radiation and other environmental factors that may cause damage to the parts or vehicle.

Of automotive packaging

is recycled

The average car has 30,000 parts

The auto industry accounts for 40% of industrial and transportation packaging

Our packaging enables manufacturers to pack more parts in a given space, reducing the amount of storage needed and improving the efficiency of the manufacturing process.

During transportation, we design our packaging to fit precisely within the cargo holds of trucks and sea shipping containers, allowing for maximum use of space while still protecting the parts and vehicles.

Shipping companies can transport more goods in a single shipment, reducing transportation costs and improving overall efficiency.

Just-in-time delivery strategies also optimize space. We deliver packaging for parts and assemblies to manufacturing plants at the exact time they are needed, reducing the need for excess storage space and improving efficiency.

At ABP, we design our automotive packaging to minimize waste and reduce environmental impact throughout the supply chain.

We use sustainable packaging materials such as biodegradable or recycled materials to reduce waste and carbon emissions. Our sustainable packaging practices help reduce the environmental impact of transportation by reducing the weight and volume of packaging materials used.

This results in fewer shipments and reduced transportation costs.

ABP’s automotive packaging protects vehicles and parts against impacts, vibrations, and environmental factors while optimizing space and being sustainable.

Check out our Innovative engineering solutions for your industrial packaging needs